电饭煲外壳注塑模设计 1087408(ID:2498962)

| # | 文件名称 | 文件大小 |

|---|---|---|

| 1 | 17545828162930.zip | 141.21M |

| 2 | bb.prt.1 | 3.13M |

| 3 | 模流分析.rar | 95.26M |

| 4 | 电饭煲外壳注塑模.dwg | 3.28M |

| 5 | 电饭煲外壳注塑模设计3D-ABS.zip | 41.53M |

| 6 | 电饭煲外壳设计说明书.doc | 893.50K |

| 7 | 222_study_分析充填时间_anim.avi | 16.48M |

| 8 | bb.stp | 2.07M |

| 9 | bb_stp.prt | 4.06M |

| 10 | 222.stl | 1.39M |

| 11 | CC.igs | 22.02K |

| 12 | CC.log | 1.94K |

| 13 | 222_study1.crc | 640B |

| 14 | 222_study1.die | 684B |

| 15 | 222_study1.err | 25B |

| 16 | 222_study1.fpo | 2.71K |

| 17 | 222_study1.lsp | 12.24M |

| 18 | 222_study1.of1 | 45.06M |

| 19 | 222_study1.of2 | 46.86K |

| 20 | 222_study1.op2 | 33.41M |

| 21 | 222_study1.out | 8.61K |

| 22 | 222_study1.ppc | 2.57M |

| 23 | 222_study1.rfn | 1B |

| 24 | 222_study1.rsp | 170.80M |

| 25 | 222_study1.smk | 207.68K |

| 26 | 222_study2Check.rfn | 1B |

| 27 | 222_study3User.rfn | 1B |

| 28 | 222_study4Doe.rfn | 1B |

| 29 | 222_study_____.sdy | 4.43M |

| 30 | 222_study_____1.rfn | 1B |

| 31 | 222_study_____1.sdy | 4.43M |

| 32 | 222_study_____2.rfn | 1B |

| 33 | 222_study_______1.crc | 167B |

| 34 | 222_study_______1.lsp | 12.24M |

| 35 | 222_study_______1.out | 1017B |

| 36 | 222_study_______1.ow3 | 2.15M |

| 37 | 222_study_______1.rfn | 1B |

| 38 | 222_study_______2Check.rfn | 1B |

| 39 | 222_study________3.sdy | 4.47M |

| 40 | 222_study________31.crc | 82B |

| 41 | 222_study________31.err | 24B |

| 42 | 222_study________31.out | 320B |

| 43 | 222_study________31.rfn | 1B |

| 44 | 222_study________32Check.rfn | 1B |

| 45 | 222_study________33User.rfn | 1B |

| 46 | 222_study________34Doe.rfn | 1B |

| 47 | molf.mpi | 259B |

| 48 | ____.rpt | 4.57K |

| 49 | report.ppt | 1.13M |

| 50 | 222_study_分析_射出重量XY_图_image.gif | 31.95K |

| 51 | 222_study_分析体积收缩率_image.gif | 35.41K |

| 52 | 222_study_分析充填区域_image.gif | 25.22K |

| 53 | 222_study_分析充填时间_anim.avi | 16.48M |

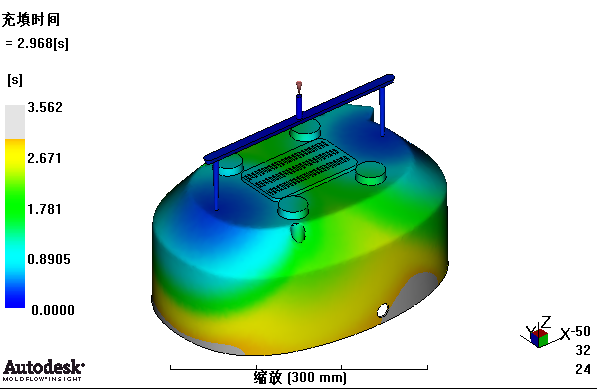

| 54 | 222_study_分析充填时间_image.gif | 35.87K |

| 55 | 222_study_分析冻结层因子_image.gif | 31.16K |

| 56 | 222_study_分析剪切速率,体积_image.gif | 24.09K |

| 57 | 222_study_分析压力_image.gif | 24.19K |

| 58 | 222_study_分析变形,所有因素X_方向_image.gif | 33.21K |

| 59 | 222_study_分析变形,所有因素Y_方向_image.gif | 33.31K |

| 60 | 222_study_分析变形,所有因素Z_方向_image.gif | 34.72K |

| 61 | 222_study_分析变形,所有因素变形_image.gif | 33.24K |

| 62 | 222_study_分析填充末端冻结层因子_image.gif | 36.24K |

| 63 | 222_study_分析填充末端压力_image.gif | 34.22K |

| 64 | 222_study_分析填充末端总体温度_image.gif | 36.35K |

| 65 | 222_study_分析壁上剪切应力_image.gif | 26.16K |

| 66 | 222_study_分析平均速度_image.gif | 28.65K |

| 67 | 222_study_分析心部取向_image.gif | 32.15K |

| 68 | 222_study_分析总体温度_image.gif | 31.06K |

| 69 | 222_study_分析推荐的螺杆速度XY_图_image.gif | 32.18K |

| 70 | 222_study_分析气穴_image.gif | 28.31K |

| 71 | 222_study_分析注射位置处压力XY_图_image.gif | 32.28K |

| 72 | 222_study_分析流动前沿温度_image.gif | 35.38K |

| 73 | 222_study_分析熔接线_image.gif | 23.47K |

| 74 | 222_study_分析第一主方向上的型腔内残余应力_image.gif | 35.39K |

| 75 | 222_study_分析第二主方向上的型腔内残余应力_image.gif | 35.38K |

| 76 | 222_study_分析缩痕估算_image.gif | 25.59K |

| 77 | 222_study_分析缩痕阴影_image.gif | 25.59K |

| 78 | 222_study_分析缩痕,指数_image.gif | 33.46K |

| 79 | 222_study_分析表层取向_image.gif | 31.50K |

| 80 | 222_study_分析达到顶出温度的时间_image.gif | 32.66K |

| 81 | 222_study_分析速度压力切换时的压力_image.gif | 34.72K |

| 82 | 222_study_分析锁模力XY_图_image.gif | 32.28K |

| 83 | 222_study_分析锁模力质心_image.gif | 28.38K |

| 84 | 222_study_分析顶出时的体积收缩率_image.gif | 35.44K |

| 85 | 360截图16331124107129148.png | 156.08K |

| 86 | 360截图16350906988997.png | 91.15K |

| 87 | 360截图16770814106120150.png | 80.39K |

| 88 | 总图.bak | 4.27M |

| 89 | 总图.dwg | 4.44M |

| 90 | 123.asm.13 | 1.69M |

| 91 | 123.crc | 377B |

| 92 | 123_cav_plate_fh001.prt.9 | 4.11M |

| 93 | 123_cav_plate_mh001.prt.10 | 4.89M |

| 94 | 123_cb_12_30.prt.3 | 141.42K |

| 95 | 123_cb_20_240.prt.3 | 169.16K |

| 96 | 123_clp_plate_fh001.prt.6 | 2.17M |

| 97 | 123_clp_plate_mh001.prt.5 | 1.98M |

| 98 | 123_e1200_10_16.prt.2 | 207.31K |

| 99 | 123_e1200_12_40.prt.1 | 218.27K |

| 100 | 123_e1200_12_45.prt.1 | 224.74K |

| 101 | 123_e1200_16_110.prt.1 | 247.66K |

| 102 | 123_e1200_16_140.prt.2 | 248.41K |

| 103 | 123_e1200_5_16.prt.1 | 186.56K |

| 104 | 123_e1200_6_20.prt.1 | 190.24K |

| 105 | 123_e1200_8_25.prt.1 | 203.59K |

| 106 | 123_e1230_12_12.prt.1 | 154.08K |

| 107 | 123_e2000_13_1_4.prt.2 | 283.66K |

| 108 | 123_e2074_10_1_4.prt.2 | 168.70K |

| 109 | 123_ejbase_plate_mh001.prt.6 | 757.53K |

| 110 | 123_ejector_pin001.prt.5 | 143.67K |

| 111 | 123_ejector_pin010-11883.prt.3 | 200.12K |

| 112 | 123_ejector_pin010-11884.prt.3 | 199.92K |

| 113 | 123_ejector_pin010-11885.prt.3 | 199.75K |

| 114 | 123_ejector_pin010-11886.prt.3 | 200.22K |

| 115 | 123_ejector_pin010-11887.prt.3 | 199.99K |

| 116 | 123_ejector_pin010-11888.prt.3 | 199.78K |

| 117 | 123_ejector_pin010-11889.prt.3 | 199.78K |

| 118 | 123_ejector_pin010-11890.prt.3 | 199.92K |

| 119 | 123_ejector_pin010-11891.prt.3 | 200.23K |

| 120 | 123_ejector_pin010-11892.prt.3 | 199.75K |

| 121 | 123_ejector_pin010-11893.prt.3 | 202.55K |

| 122 | 123_ejector_pin010-11894.prt.3 | 185.27K |

| 123 | 123_ejector_pin010-11895.prt.3 | 185.33K |

| 124 | 123_ejector_pin010-11896.prt.3 | 185.33K |

| 125 | 123_ejector_pin010-11897.prt.3 | 185.76K |

| 126 | 123_ejret_plate_mh001.prt.7 | 3.46M |

| 127 | 123_gba_50_59.prt.3 | 317.07K |

| 128 | 123_gbb_50_39.prt.3 | 253.74K |

| 129 | 123_gpa_50_49_197.prt.3 | 397.40K |

| 130 | 123_int_plate_fh001.prt.5 | 1.17M |

| 131 | 123_locating_ring2.prt.3 | 285.36K |

| 132 | 123_machine.prt.3 | 287.28K |

| 133 | 123_risers_l_mh001.prt.4 | 631.23K |

| 134 | 123_risers_r_mh001.prt.5 | 653.53K |

| 135 | 123_sjac_20_5_0_30_16_0.prt.3 | 296.85K |

| 136 | 123_skeleton.prt.3 | 254.13K |

| 137 | 123_sp002.prt.1 | 841.65K |

| 138 | 123_sp003.prt.1 | 842.54K |

| 139 | 123_spn_spc_50_59_400.prt.4 | 852.05K |

| 140 | 123_spring10.prt.3 | 5.08M |

| 141 | bb.prt.7 | 4.01M |

| 142 | drw0002.drw.2 | 4.58M |

| 143 | hk.prt.6 | 129.91K |

| 144 | hk1.prt.5 | 144.98K |

| 145 | mfg0001.acc | 894B |

| 146 | mfg0001.asm.3 | 2.00M |

| 147 | mfg0001.crc | 381B |

| 148 | prt0001.prt.2 | 33.60K |

| 149 | qjk.prt.3 | 1.58M |

| 150 | sm.prt.7 | 1.30M |

| 151 | xd.prt.7 | 86.96K |

| 152 | xiaolagan.prt.1 | 350.84K |

| 153 | xiedaozhu.prt.2 | 98.57K |

| 154 | xiedingzuo.prt.2 | 114.94K |

| 155 | xj.prt.3 | 412.44K |

| 156 | xm.prt.8 | 2.36M |

| 157 | 123_asm.stp | 13.64M |

| 158 | 123__out.log.1 | 5.57K |

| 159 | bb.stp | 2.07M |

| 160 | bb__out.log.1 | 5.05K |

| 161 | chanpin.prt.1 | 4.34M |

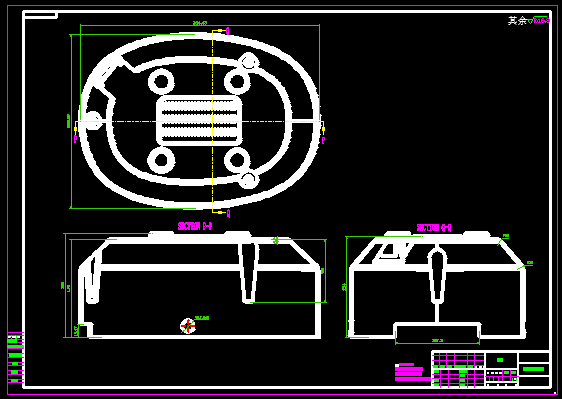

| 162 | 主流道,分流道设计.png | 89.96K |

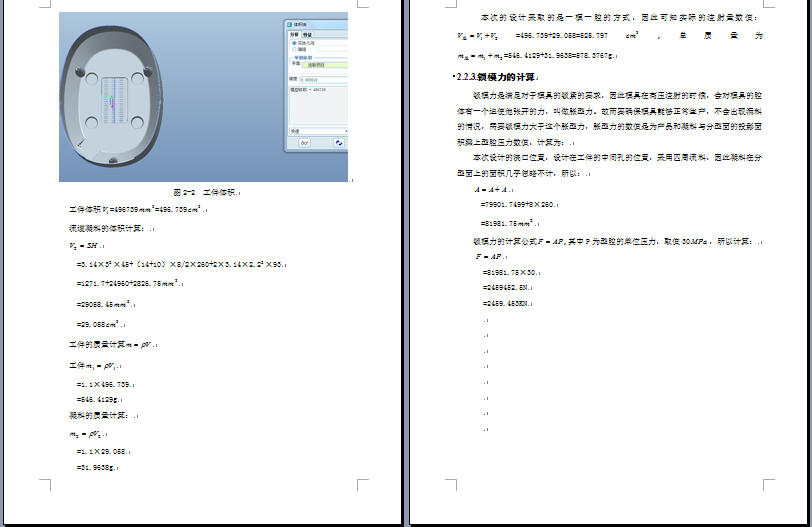

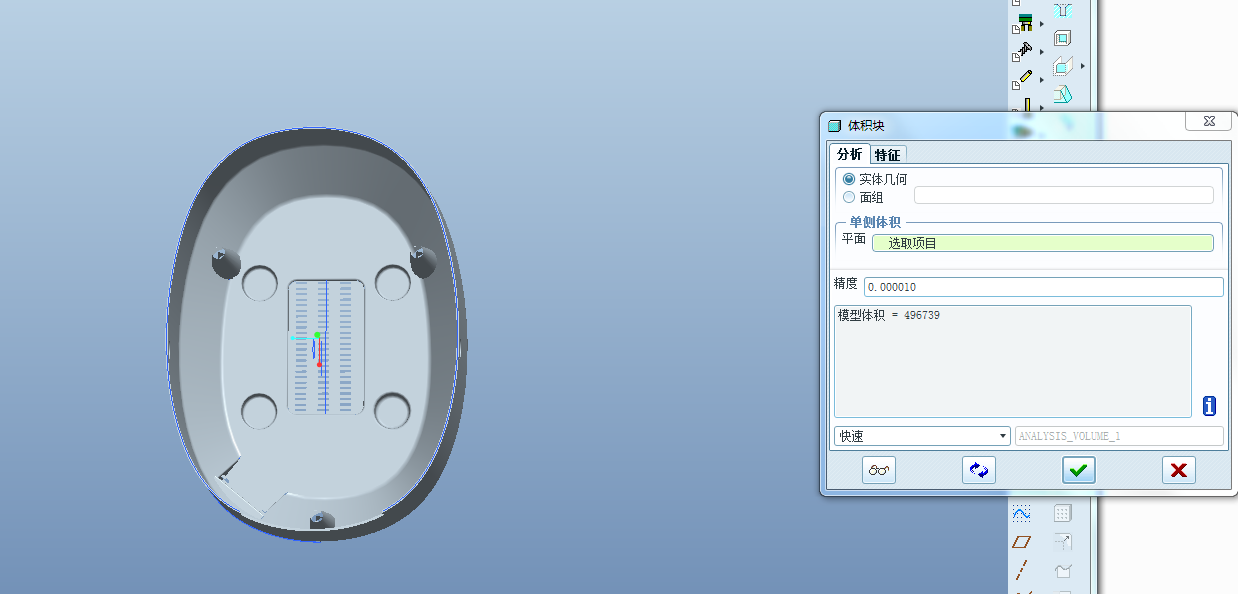

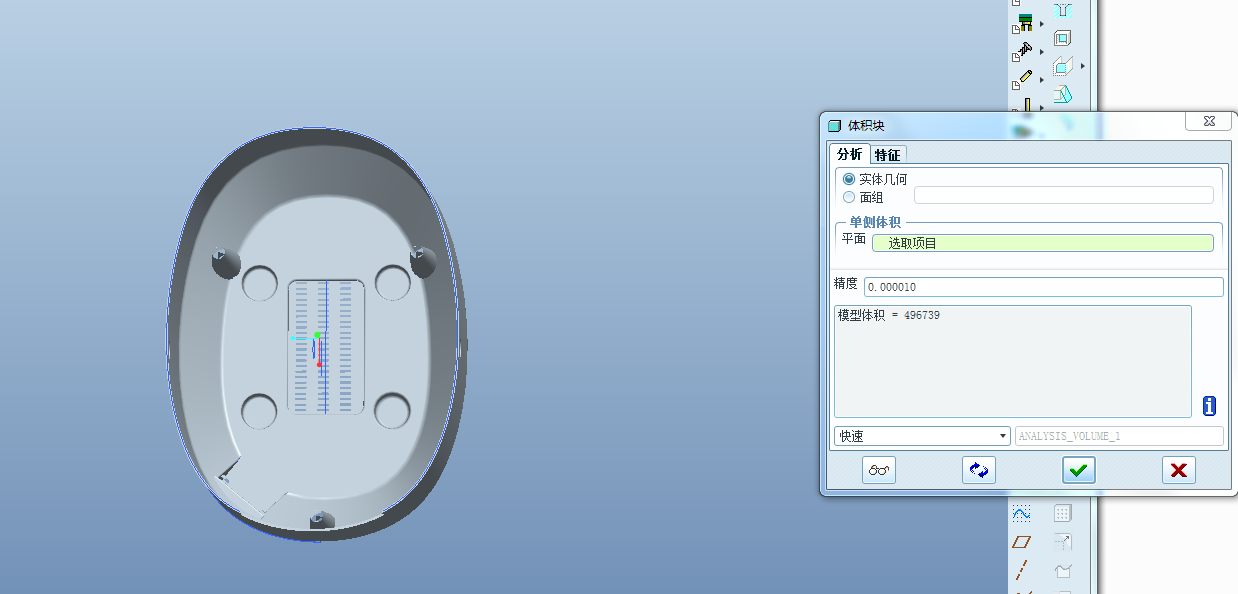

| 163 | 体积计算.png | 67.13K |

| 164 | 凹模设计.png | 79.14K |

| 165 | 动模座板,顶杆垫板.png | 21.09K |

| 166 | 型腔固定板,拔料板.png | 25.14K |

| 167 | 型芯固定板,滑块.png | 37.19K |

| 168 | 型芯,型腔.png | 32.34K |

| 169 | 字数统计,目录.png | 71.14K |

| 170 | 定位圈,浇口套,斜顶.png | 20.73K |

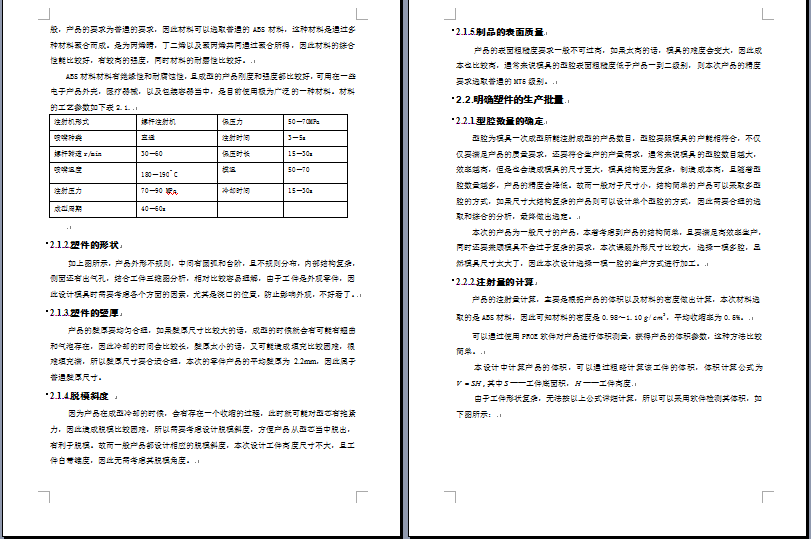

| 171 | 定模座板.png | 18.90K |

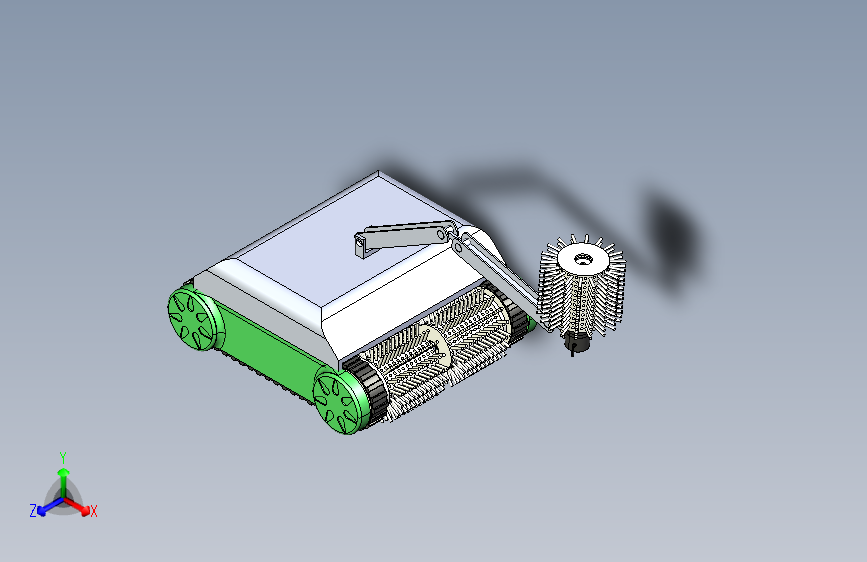

| 172 | 工件3D图.png | 91.15K |

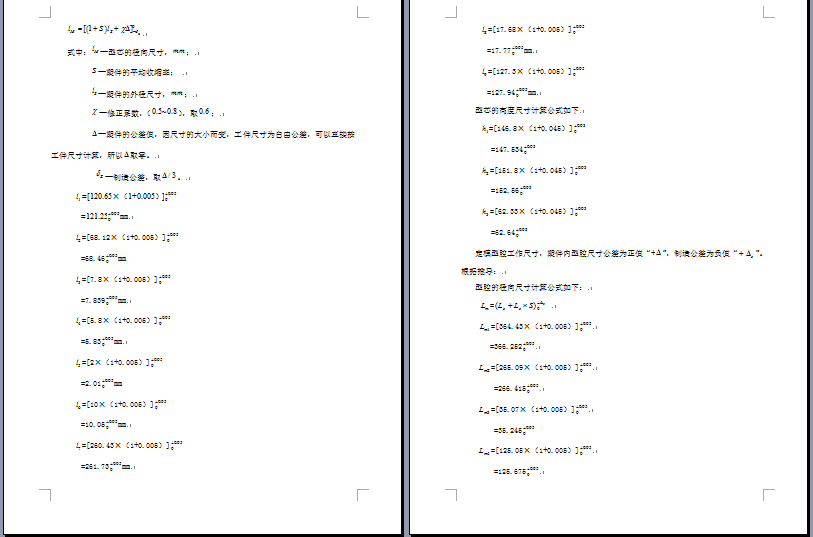

| 173 | 工件分析.png | 88.76K |

| 174 | 工件图.png | 14.25K |

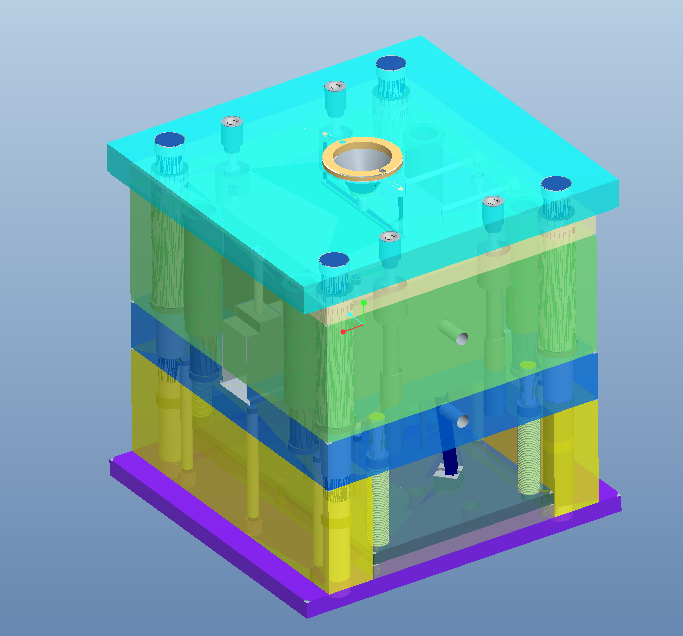

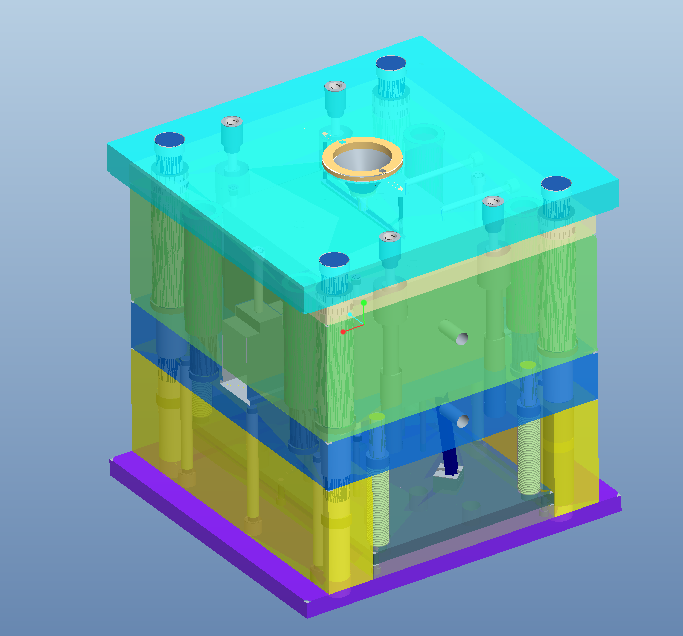

| 175 | 成型尺寸计算.png | 37.17K |

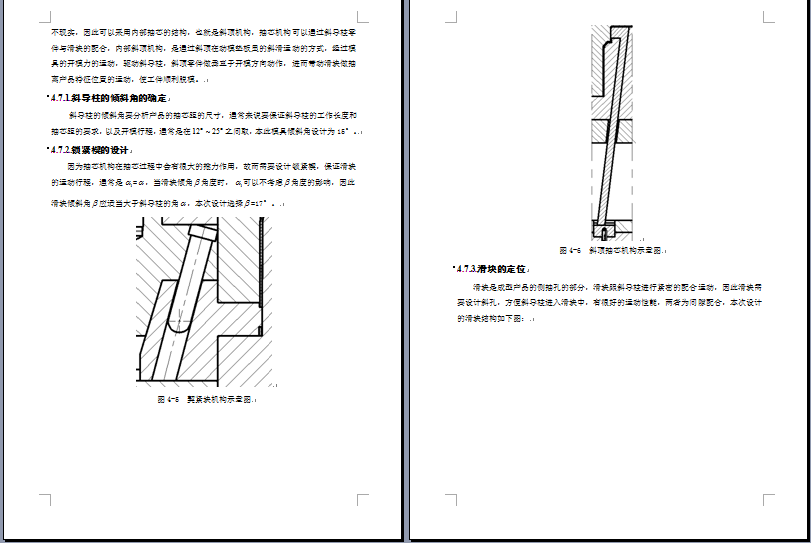

| 176 | 抽芯设计.png | 72.17K |

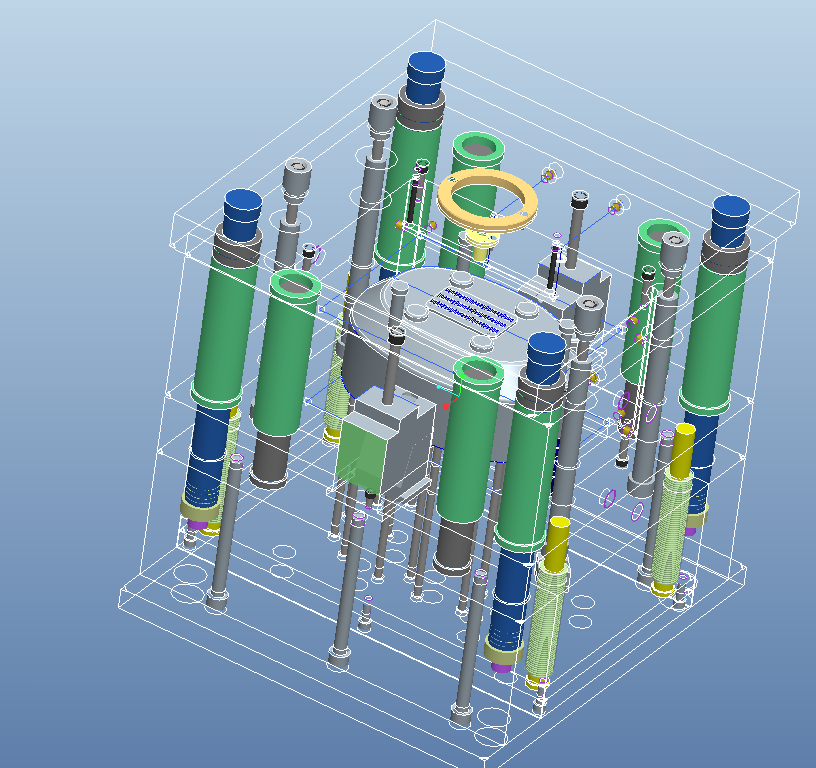

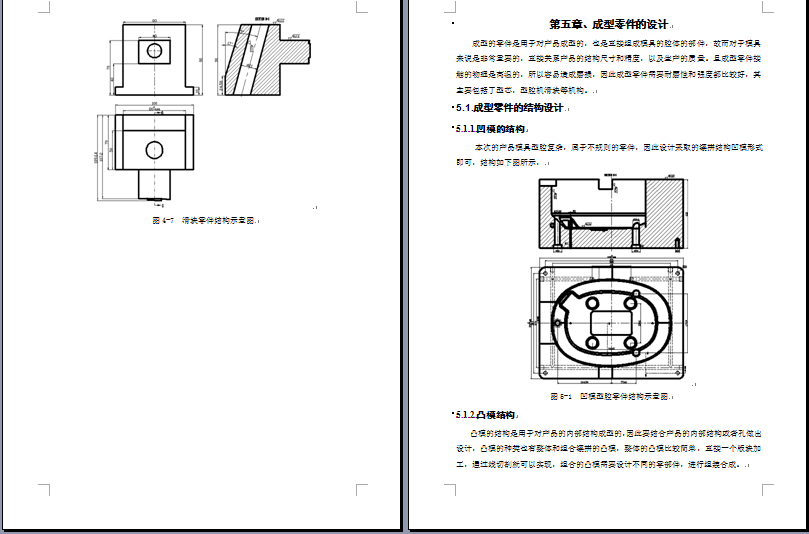

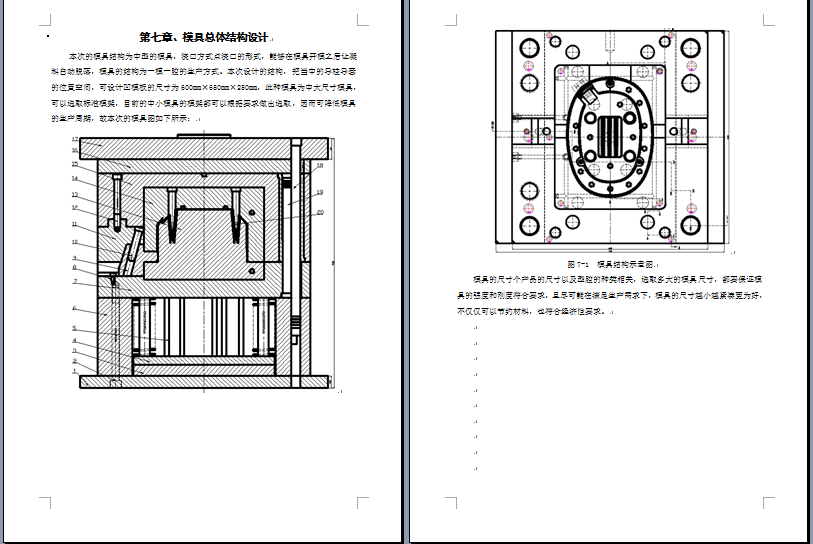

| 177 | 模具3D.png | 80.39K |

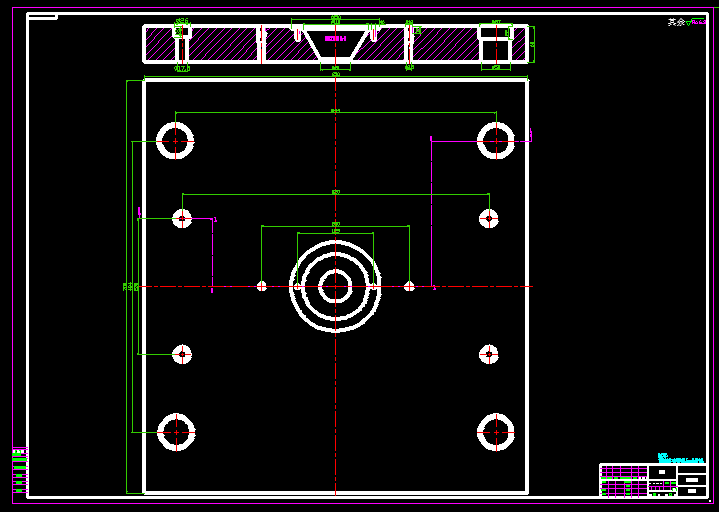

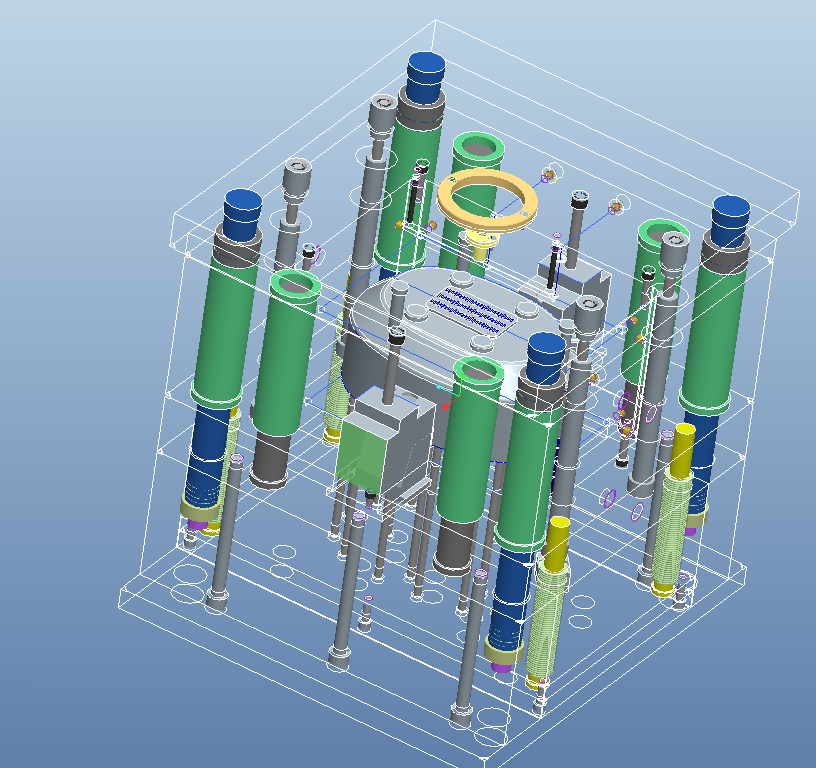

| 178 | 模具3D内图.png | 156.08K |

| 179 | 模具结构设计.png | 132.11K |

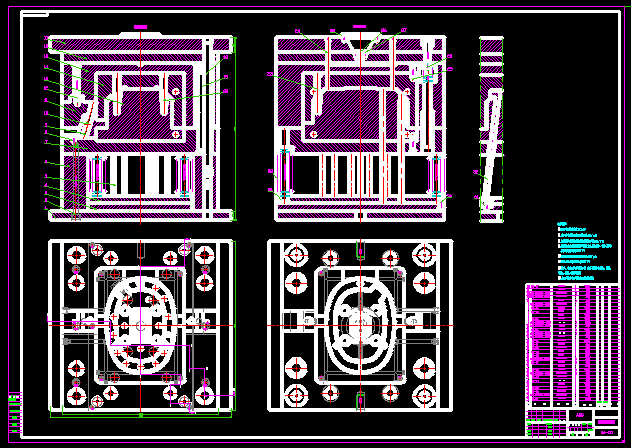

| 180 | 模具装配图.png | 46.38K |

| 181 | 模流分析.png | 68.90K |

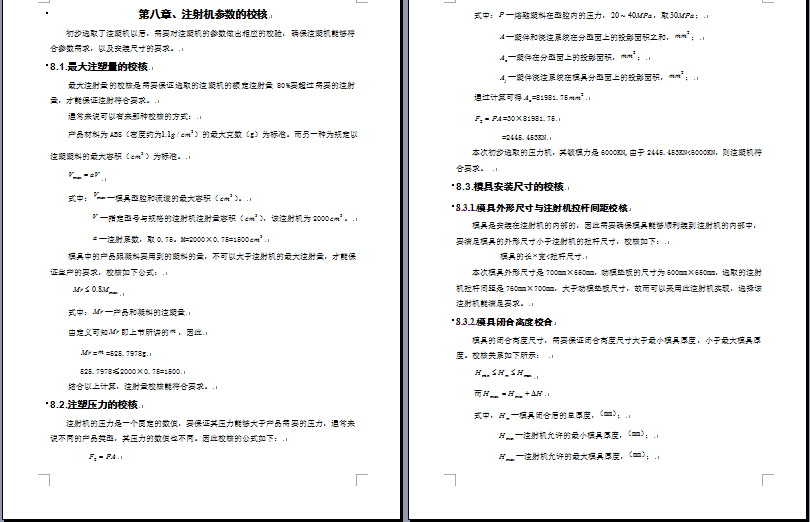

| 182 | 注射机校核.png | 69.16K |

| 183 | 注射机选择,分型面选择.png | 76.96K |

| 184 | 顶杆固定板,垫铁.png | 22.50K |

此图纸下载需要1000金币

立即下载

发布者

懵懂得帽子

创作: 24569

粉丝: 676

加入时间:2023-06-16

模型信息

图纸格式:prt,dwg,stp,stl,igs,asm

文件大小:144.59M

所需金币:1000

上传时间:2025-08-08 00:07:21

是否可编辑:可修改,包括参数

版本:PROE*CREO Wildfire 5.0

标签

图纸简介

版权说明

用户在本站上传的作品如侵犯到您的权益,请与本站管理员联系删除。用户在本站下载的原创作品,只拥有作品的使用权,著作权归原作者所有,未经合法授权,用户不得以任何形式发布、传播、复制、转售该作品。

作者其它图纸 查看更多

1.png)

2.png)

3.png)

4.png)

0.png)

0.png)

0.png)

0.png)

0.png)

0_0_364.png)

0.png)

0_0_364.png)

0.png)

0.png)

0.jpg)

0.png)

0.png)

0.png)

0.png)

0.png)

0.png)

0.png)

0.png)

0.png)

0.png)

0.png)

0.png)

0.png)

0_0_364.png)

0.png)

0.png)

0.png)